Contact Us

Get in touch with the product manager Petteri Viinanen (040 585 5485, info@sysi.fi) and we’ll tailor a solution to your need.

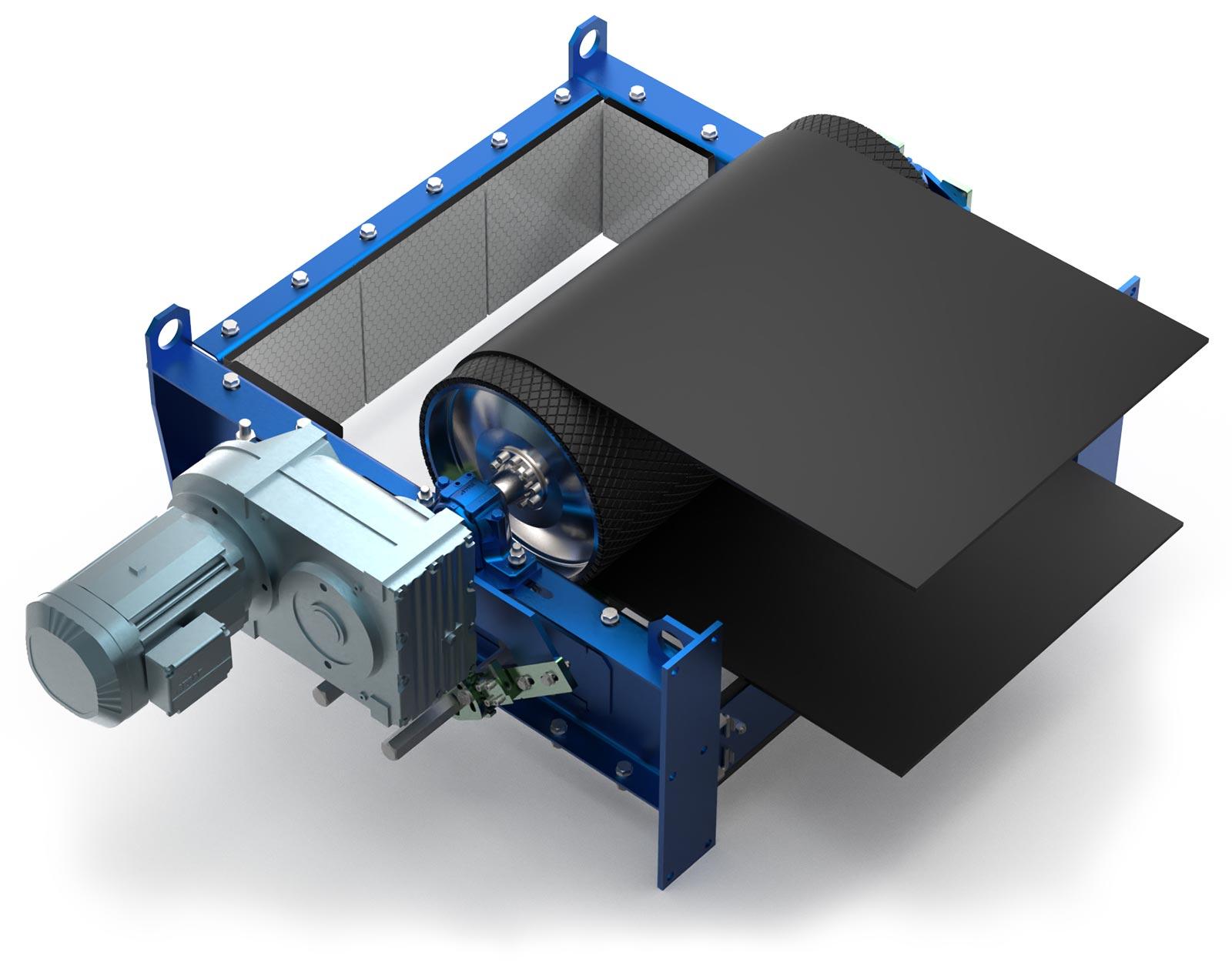

Just like the transfer points, discharge stations are unique individuals. Or at least they should be. The next conveyor location, the chute height and material properties define the limitations on the geometry. Correct design allows sealing the transfer point well, starting from the incoming material side, thus the volume of the air carrying the dust, can be reduced significantly.

So, we start with the geometry and then work ourselves to sealing the belt cleaners, pulley shafts, space between the chute and return belt, belts and carry belt and hood. At the same time keeping in mind, that the inspection and maintenance hatches and openings must be as big as possible.

You can calculate or simulate the discharge parable of the material to get to a pretty good result, but still the possibility to adjust the drive pulley location is cheap way to ensure that changes in material properties do not need to result in the transfer point becoming a source of problems.

This product is an example of a solution tailored to one of our customers. When necessary, we do design the components to suit the customer’s need.

Get in touch with the product manager Petteri Viinanen (040 585 5485, info@sysi.fi) and we’ll tailor a solution to your need.