Designing the equipment for the actual application is an important aspect in boosting your uptime. It’s actually not just the equipment, but how it is supported, how is the chute is designed, which places need a service platform and where do you need lifting points for maintenance. These are the normal aspects we go through on the projects.

Product groups

We offer the following equipment.

Screens

Our cooperation partner in screens is mainly Danish SKAKO Vibration A/S. SKAKO has developed and manufactured screens for decades and to a large variety of different applications and conditions. The smaller screens are typically equipped with electromechanical or electromagnetic vibrators, the larger ones having eccentric drives. Tailoring the screens so that they fit on the existing foundations or supports, is a typical task. Why should time and money be spent on making good old supports again.

When it comes to the screening media or wear protection, we’ll be glad to consult you and propose solutions from our wide range of possibilities.

Feeders

Sysi represents the Danish SKAKO Vibration A/s feeders. SKAKO has been developing and manufacturing feeder for decades to various industries, applications and conditions.

The design is mainly a modular one and highly standardized, covering a very large range of feeders with accessories. In feeders we use the electromagnetic vibrators by SKAKO, since the design is made under consideration of frequent starts and stops as the case is in dosing applications.

As an alternative, electrical vibrating motors are also available. The capacities range from a fee hundreds of kilos to 1600 tons per hour and from very fine materials to grizzlies feeding 400mm rocks.

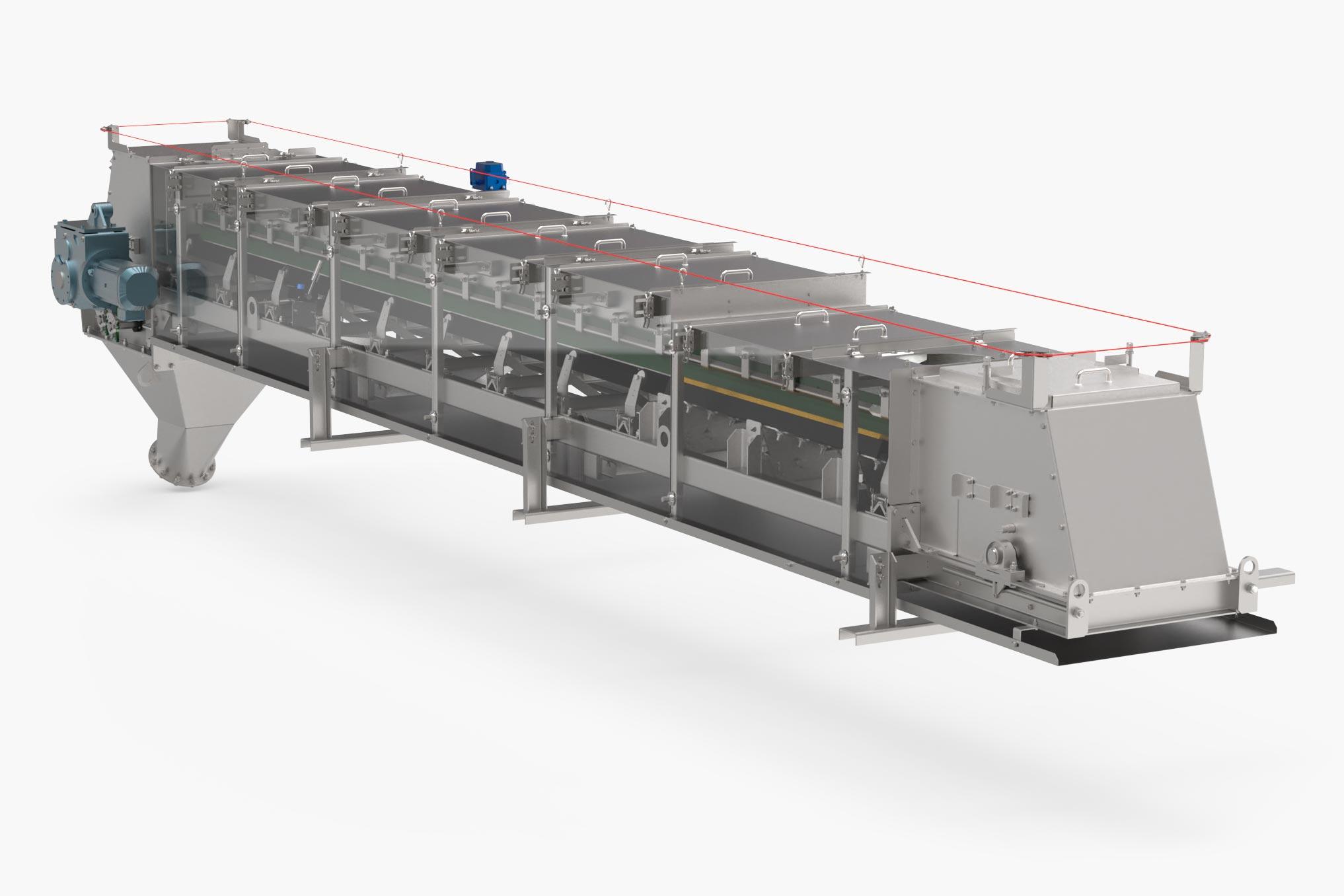

Belt conveyors

Over the years we have developed standardized solutions for belt conveyors. With standardization we mean the functionality, not the design. In our words, standardization means you will always get the same maintenance friendly solutions that will help you keep the operating costs down.

The longer the maintenance intervals and the less time needed for maintenance, the more production you can make.

Each conveyor is tailored to the application, but the functionality is what comes as the Sysi standard.

Dust suppression

When discussing dedusting measures, we start by putting the mechanical prequisites in top condition first. With small things, it is possible to control the airflow in the chute and to seal the equipment so that you can control the dust.

Depending on the materials and process, you may want to get rid of the fines or you may want to return them to the material flow for example with a very fine water fog. In some cases, even a small amount of moisture will be a problem, which means that a decentralized dedusting unit could be the solution…or then to use a larger dedusting unit gathering the dust from various locations.

Again, learning about the material properties and operating conditions is the key information to the engineering.

Tramp metal removal

It’s not always clear where the metal parts are coming to the material flow, but the consequences unfortunately quite often are.

Steinert GmbH magnets are known for their efficiency and there is a wide range of different solutions for metal separation, from belt magnets to magnetic pulleys, drums, permanent magnets etc. So, whether you need to pick up bigger particles from coarse material or finer particles from finer material, there will be a solution.

The magnet itself is not always the only thing to look at. You might get a nice performance improvement by adjusting the troughing angle, the belt conveyor speed or the tramp metal through geometry.

Considering the damages caused by metal parts, an investment in tramp metal removal is often worth it.

Metal detectors

A metal piece stuck on a concrete block might not be removed by a magnet or it might not be possible to remove. Sometimes small metal particles hide themselves in the material bed in a way that the magnets wont find them. In these cases the metal detectors from EAB Rheinhausen are an effective way to make sure that the material is clean from any unwanted metal particles and that the crushers and grinders will have a bit longer lifetime.

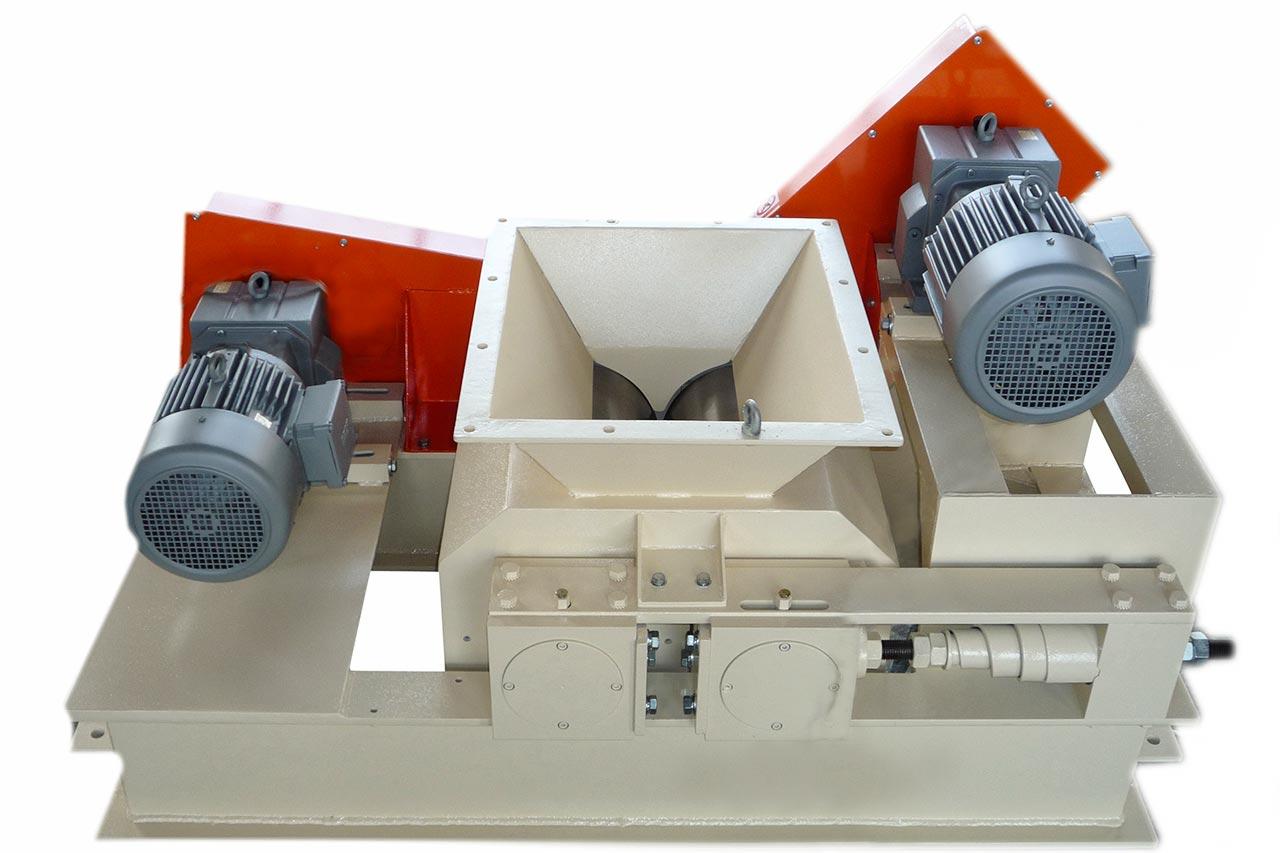

Crushers

For various materials, we supply small capacity crushers and grinders.

Cimma Ing. Morandotti & C. Srl has decades of experience from different crushing methods and a good variety of different crushing solutions from impact crushers to roll grinders.

Hoisting systems

Ore hoisting is typically the most economical way when the mine depth is around 300-400 m. Köepe-, Blair-, single- and double drum hoisting machineries are made by Siemag Tecberg, Germany.

Due to the size of the projects, their long duration and extensive technical specification and installation works, the local partner has it’s place in the projects.

In these projects we are there from the very beginning, discussing the technical specification, defining the scope, interfaces, installation and until the end of the project with installation, startup and maintenance.

Grapples

Grapples are tailored sturdy solutions meeting the customer needs. Whether it should be a rope operated, hydraulic or electrical grapple, we have it.

Advantages

Conveyor and modernisation solutions.

Quality

Our and our principals knowhow in your service.

Turn key

Turn-key deliveries.

Customization

Considering the material and the customer’s needs.

Project

Clear project management.