Components

Increase the maintenance intervals and the reliability of your equipment with our components

Our offering comprises of components and wear parts for belt conveyors, screens and feeders among other applications. Most of our products are developed in our wide network of partners and they have been tested around the world.

In addition to these, our own R&D has created a nice selection of solutions easing the maintenance and making the components last longer. As a result, you’ll have safer equipment with faster maintenance and a boost in the uptime.

Product groups

We offer components in the following areas.

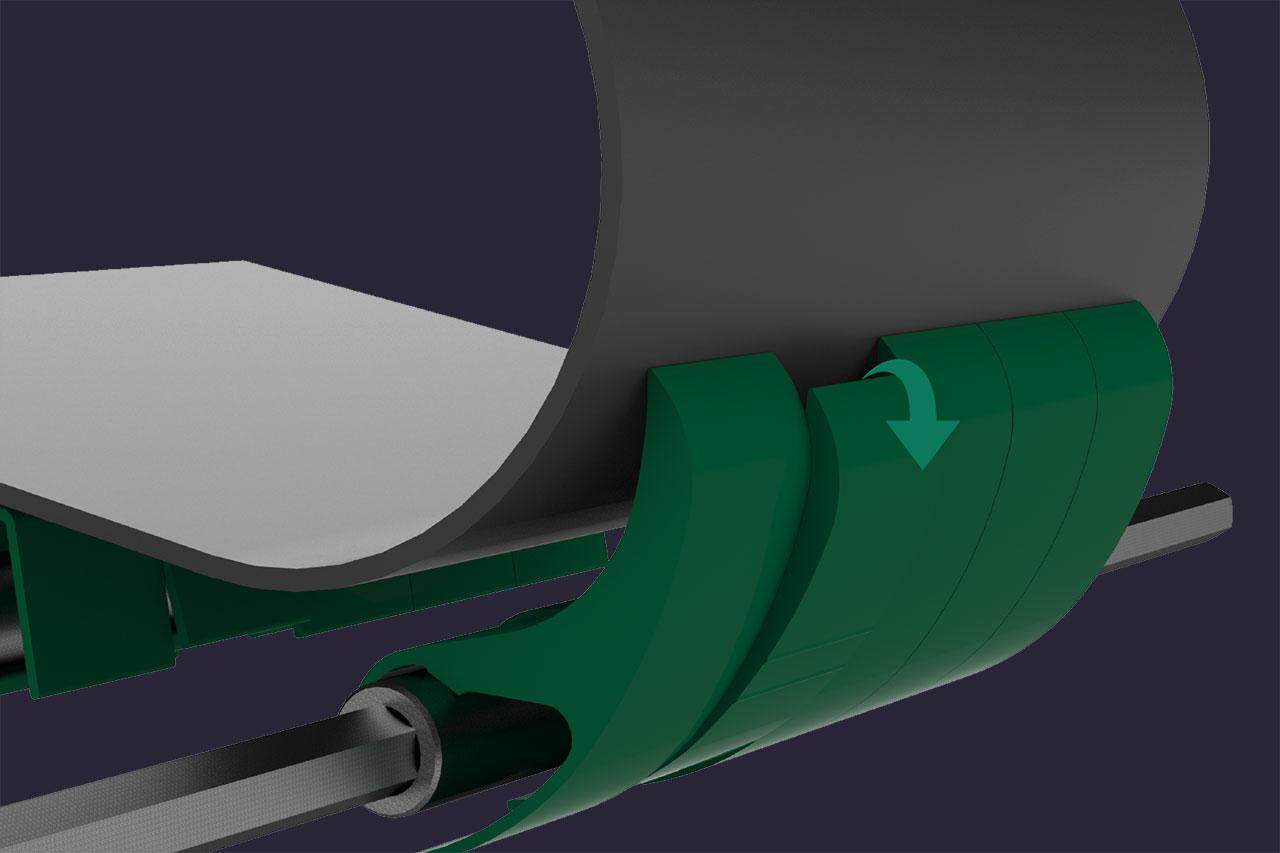

BELT TRACKING

Belt mistracking can cause unwanted interruptions in production, damage the belt and cause spillage. With the very effective CenTrax belt trackers and rollers, we will solve also other problems, not just the belt mistracking.

First you need to get rid of dirt and other reasonably easily manageable issues. Then you add the necessary, but only the necessary amount of trackers and rollers.

Trackers, rollers and their spare parts are found in our stock.

BELT CLEANERS

Transfer points are typically the most common source of problems. Wearing, spillage, off-tracking and unexpected production stops.

The sturdy impact bed designed by Sysi, provides a very good support for the belt, thanks to the adjustment possibilities. Good support in the feeding area makes it possible for the skirtboard sealing to reach a long lifetime and to reduce the spillage in a remarkable way. For very fine materials the Starseal double sealing system provides the best solution. For coarser material the Spill-EX with individually adjustable rubber blocks or the SEAL series from Sysi’s own development, with AISI316 steel parts and individually adjustable polyurethane block are the best solutions.

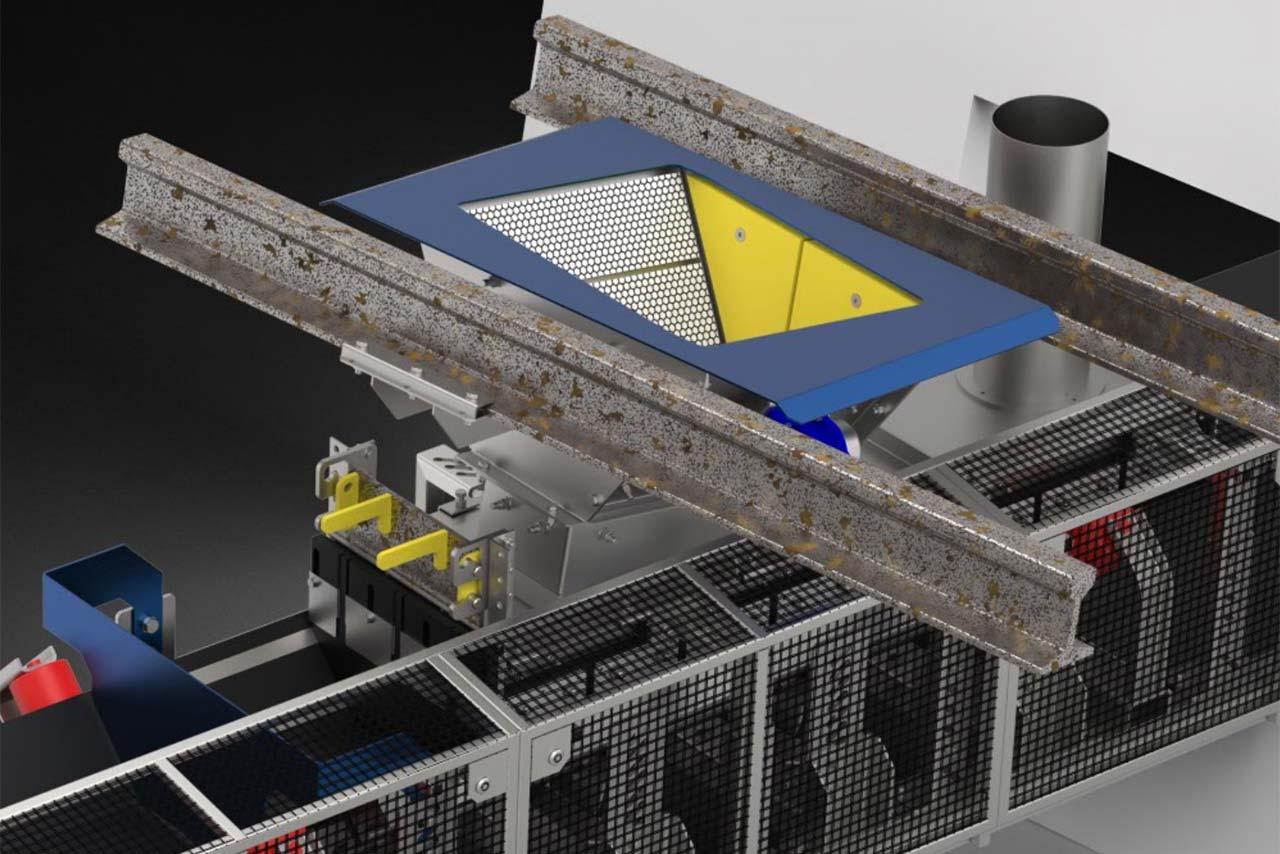

TRANSFER POINT COMPONENTS

Transfer points are typically the most common source of problems. Wearing, spillage, off-tracking and unexpected production stops.

The sturdy impact bed designed by Sysi, provides a very good support for the belt, thanks to the adjustment possibilities. Good support in the feeding area makes it possible for the skirtboard sealing to reach a long lifetime and to reduce the spillage in a remarkable way. For very fine materials the Starseal double sealing system provides the best solution. For coarser material the Spill-EX with individually adjustable rubber blocks or the SEAL series from Sysi’s own development, with AISI316 steel parts and individually adjustable polyurethane block are the best solutions.

ROLLER FRAMES, ROLLERS AND PULLEYS

Conveyor rollers are one the cheapest conveyor components, but they can cause a good amount of destruction and maintenance work if they are not properly chosen. When necessary, we will take the conveyor technical data, calculate loads and choose the right roller for your application.

Besides the traditional steel rollers, we offer the steel rollers with a thick HDPE shell, HDPE bearing housings and multiple lip seals. In practise a roller that has a way longer lifetime, which wearing you can notice easily with your eyes much before you are starting to damage your belt. So, pure saving in operating costs and a good increase in safety and reliability.

SCREENING MEDIA

Highly wear resistant and high quality screening media, accessories and screen wear protection for various industrial applications.

Depending on the application, rubber, polyurethane or metal can be the best one. Different qualities, hardnesses and combinations are naturally available. The manufacturers we work with have years of experience in screening and of the materials used. This will give you the possibility to take advantage of the best possible solution for your screening operations.

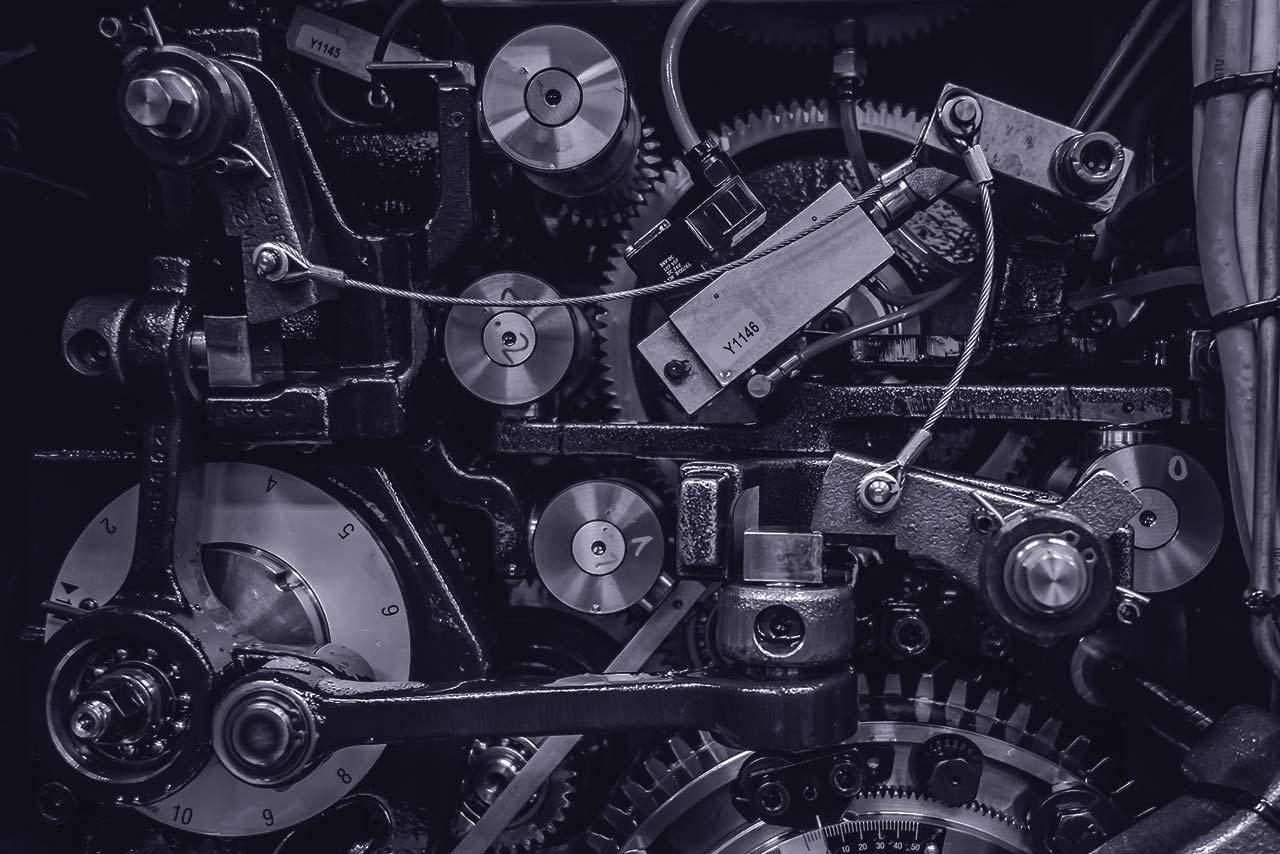

MAINTENANCE AIDS

Conveyor maintenance can be annoying if you need to spend your time with unnecessarily difficult fasteners and systems. The safety mesh bolts are jammed, the belt cleaner saddle pipe opening is leaking, the screen sealing profiles won’t stay on anymore and you need to pull out tens of meters of E-stop wire to be able to remove the shields.

Yes, these did annoy us too, but not any more.

Advantages

Conveyor and modernisation solutions.

Effectiveness

Long service life, high reliability.

Speed

Fast maintenance, short stop.

Savings

Long lifetime and reliability means savings.

TAILORING

A solution for each application.