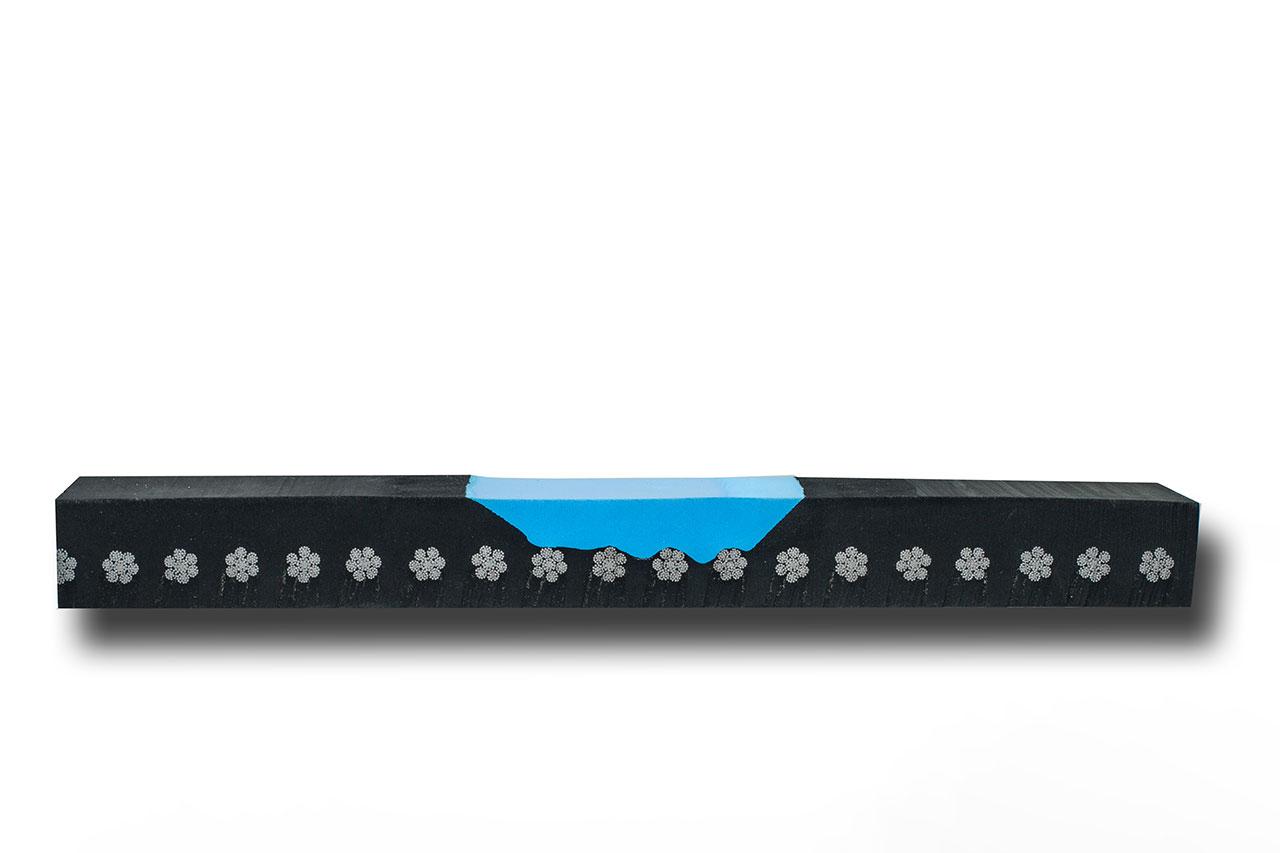

LUWIREP® 70 belt repair

A fast and easy way for belt repairs. With Luwirep, you will need only small and light weight tools. It allows you to repair belt damages in just 40 minutes and you can start production immediately after the work is done. The material properties have been optimized for rubber especially with respect to adhesion and abrasion resistance. The repair material cartridges can be sealed after use, so that the leftovers can be used next time.

Contact Us

Get in touch with the product manager Teppo Lehtinen (050 438 1191, info@sysi.fi) and we’ll tailor a solution your need.