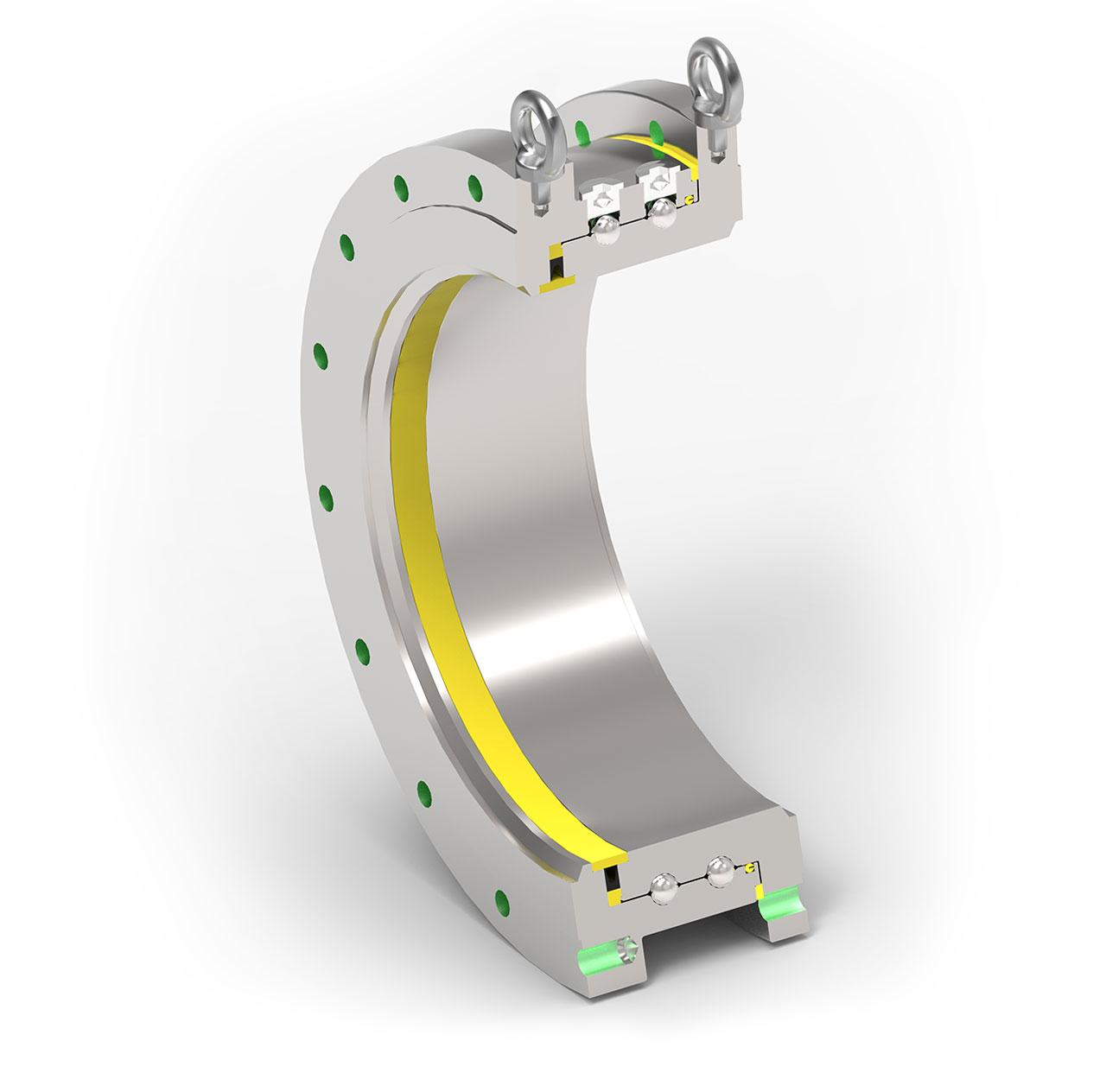

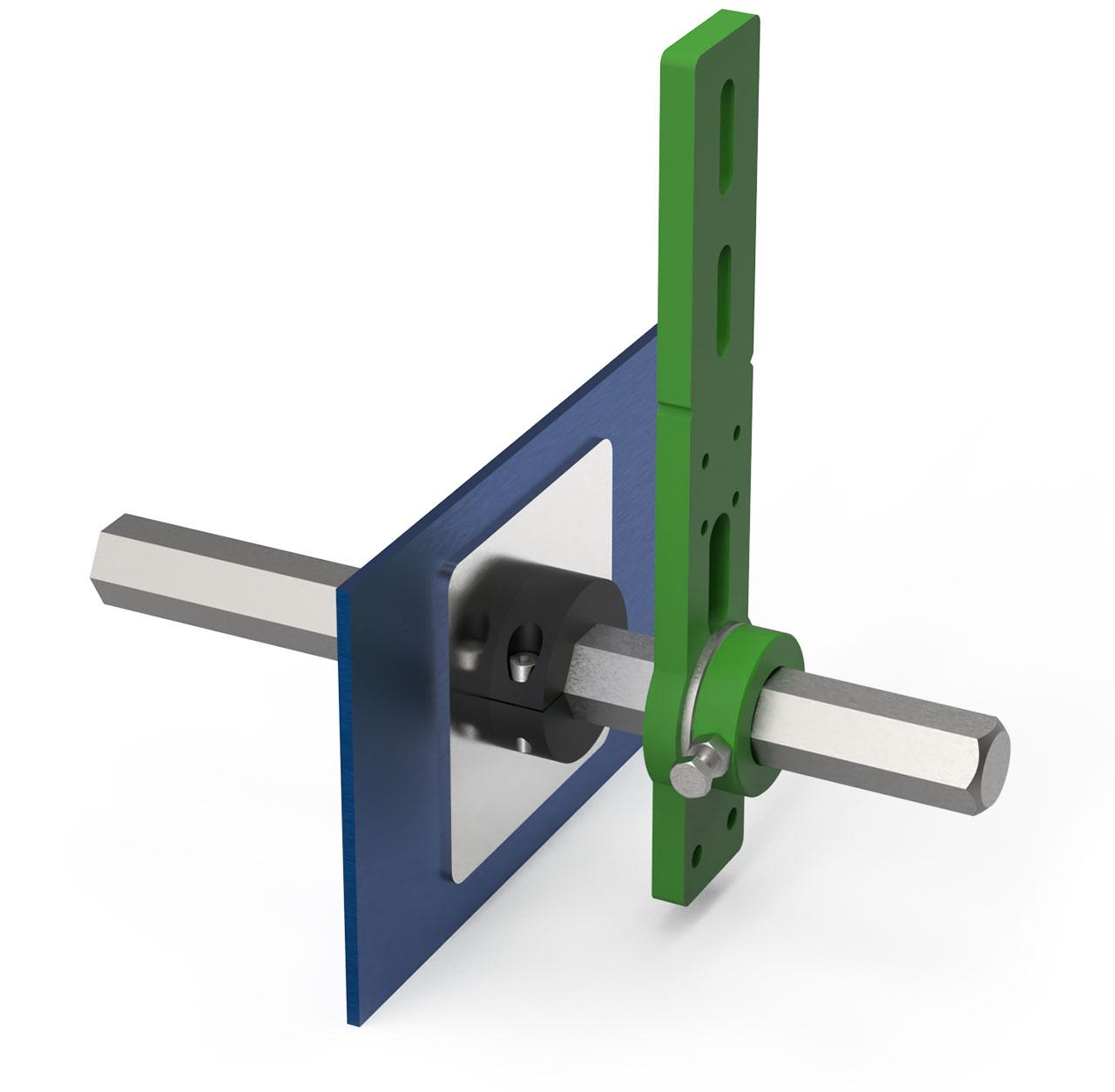

Metal detectors

A metal piece stuck on a concrete block might not be removed by a magnet or it might not be possible to remove. Sometimes small metal particles hide themselves in the material bed in a way that the magnets wont find them. In these cases the metal detectors from EAB Rheinhausen are an effective way to make sure that the material is clean from any unwanted metal particles and that the crushers and grinders will have a bit longer lifetime.

Contact Us

Get in touch with the product manager Teppo Lehtinen (050 438 1191, info@sysi.fi), and we’ll tailor a solution to your need.