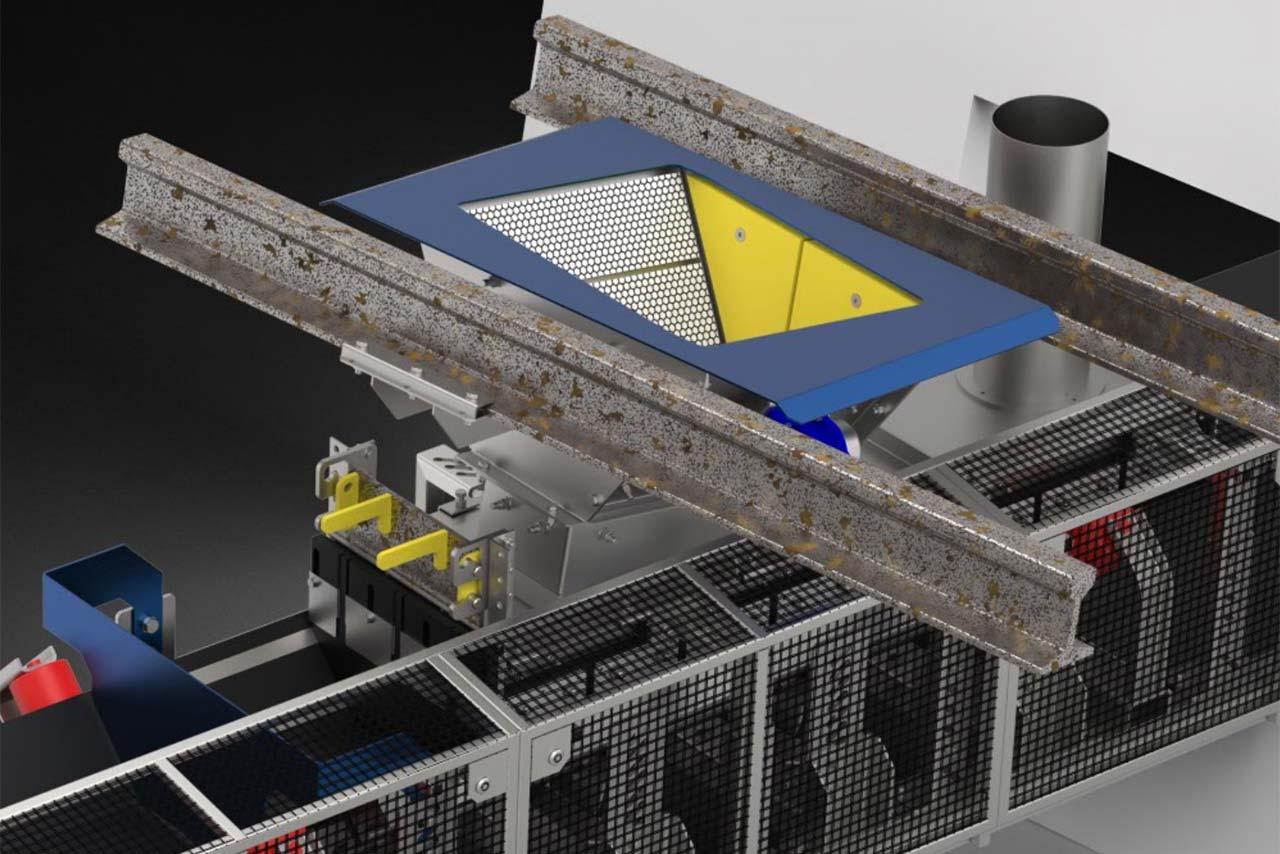

Roller frames, rollers and pulleys

Kuljetinrullat ovat yksi halvimmista kuljettimen komponenteista, mutta voivat saada melkoisesti tuhoa ja työtä aikaan, mikäli niiden valinta ei ole suoritettu oikein. Laskemme tarvittaessa kuljettimen teknisten tietojen avulla sopivat rullat ja valitsemme käyttökohteeseen järkevimmän vaihtoehdon.

Perusteräsrullien lisäksi valikoimasta löytyy raskaan sarjan HDPE pintaiset teräsrullat, joissa on monihuulitiivistys ja hyvin paksu HDPE pinta. Käytännössä rulla, jonka kestoikä on hyvin pitkä ja jonka kulumisen huomaan paljon ennen kuin saavutetaan edes teräs vaippaa. Siis silkkaa käyttökustannusten säästöä ja turvallisuutta jo kevyemmän painonsa ansiosta.

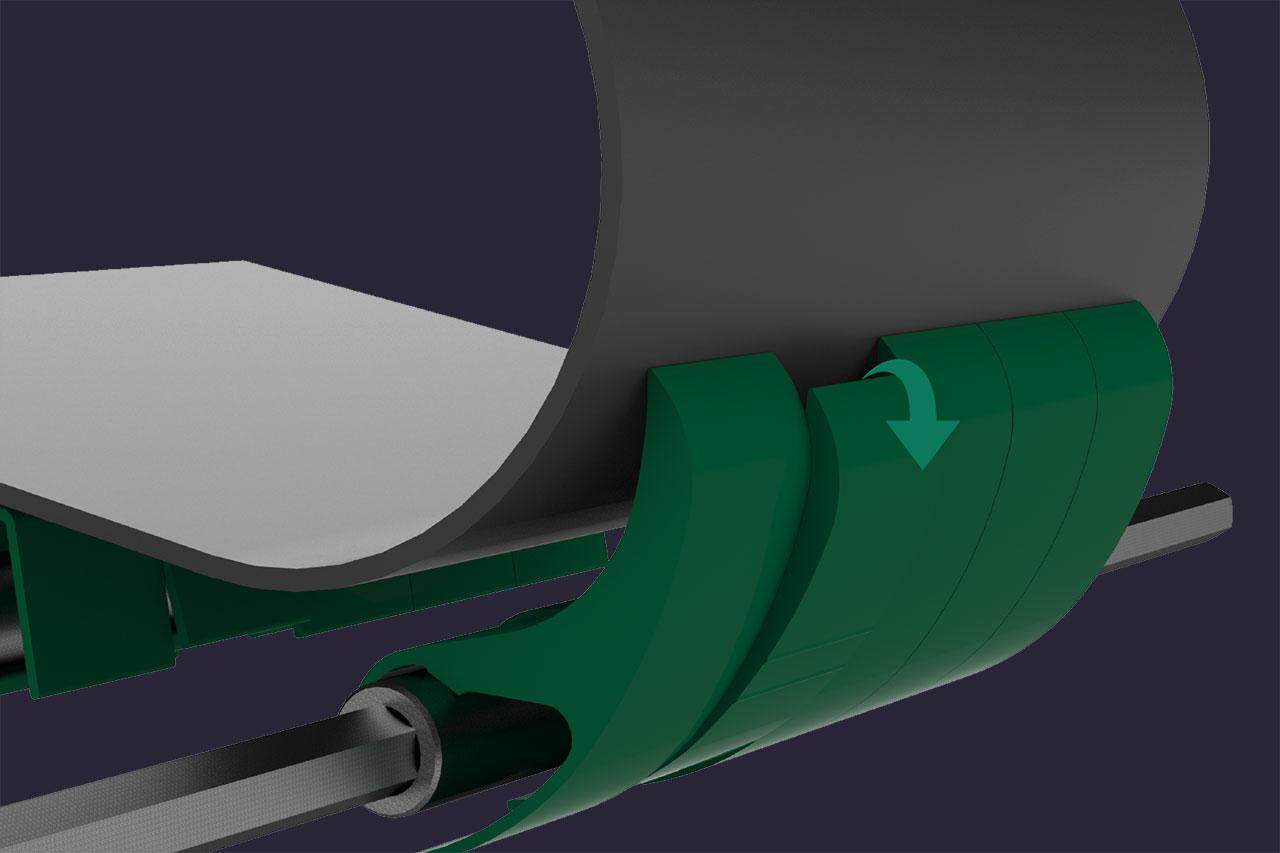

Kuljetinrummuissa teemme yhteistyötä HSD Schäfer GmbH:n kanssa ja valikoimasta löytyy varmasti riittävän kestävät rummut kohteeseen kuin kohteeseen. Pinnoituksissa tarpeen mukaan myös erilaiset liimatut, vulkanoidut tai pultattavat keraamipinnoitteet.

Contact Us

Get in touch with the product manager Teppo Lehtinen (050 438 1191, info@sysi.fi) and we’ll tailor a solution your need.