Conveyor covers

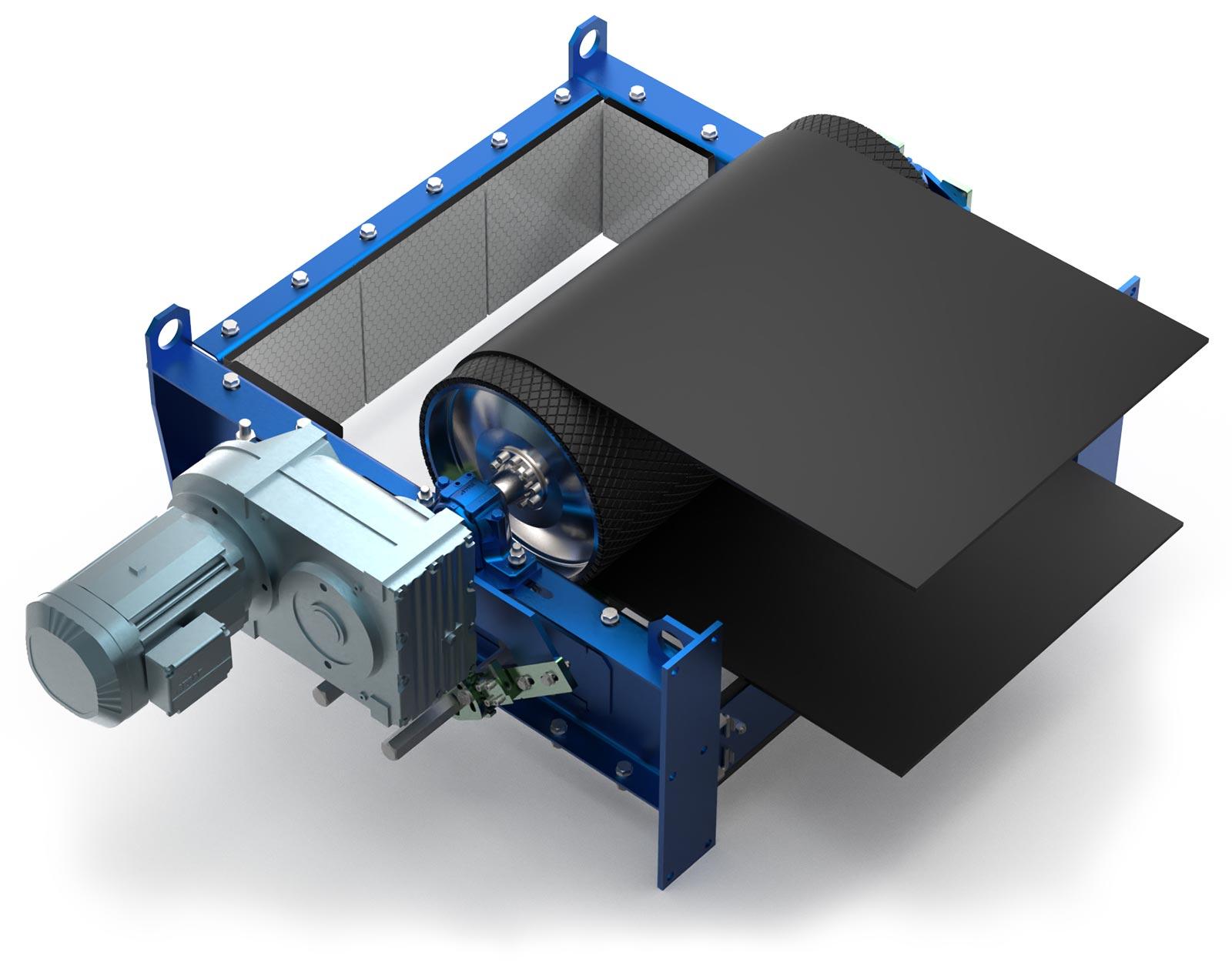

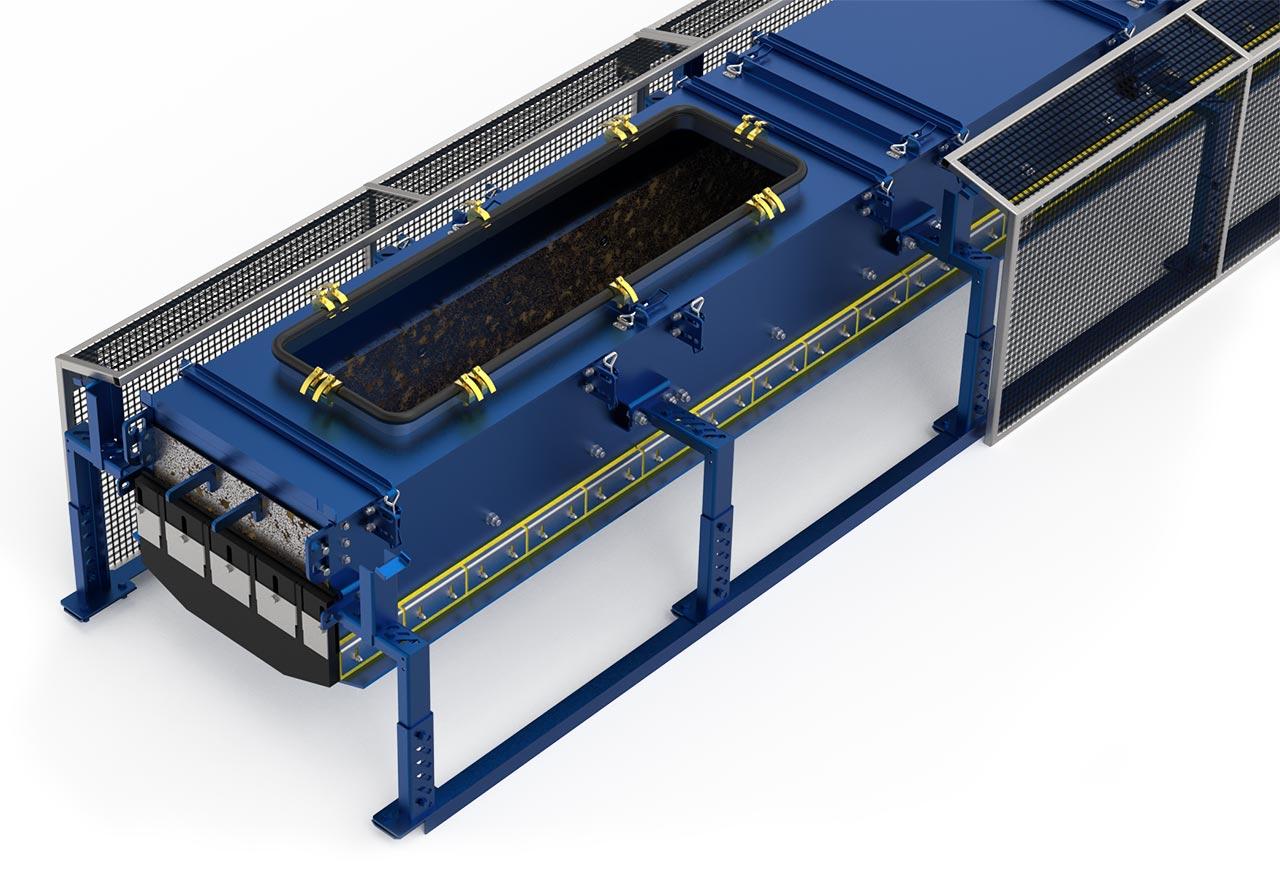

The conveyor covers are there to ensure that there is as little spillage as possible and that the dust stays inside the transfer point and can be directed to the dedusting system. The larger the cover cross section, the slower the air flow inside it and the shorter the distance the dust needs to fall back to the material flow.

With a well adjustable impact bed, a good support is provided for the belt at the transfer point. With retractable roller frames, you can bring the wear plates very close to the belt and get more life time for the skirtboard.

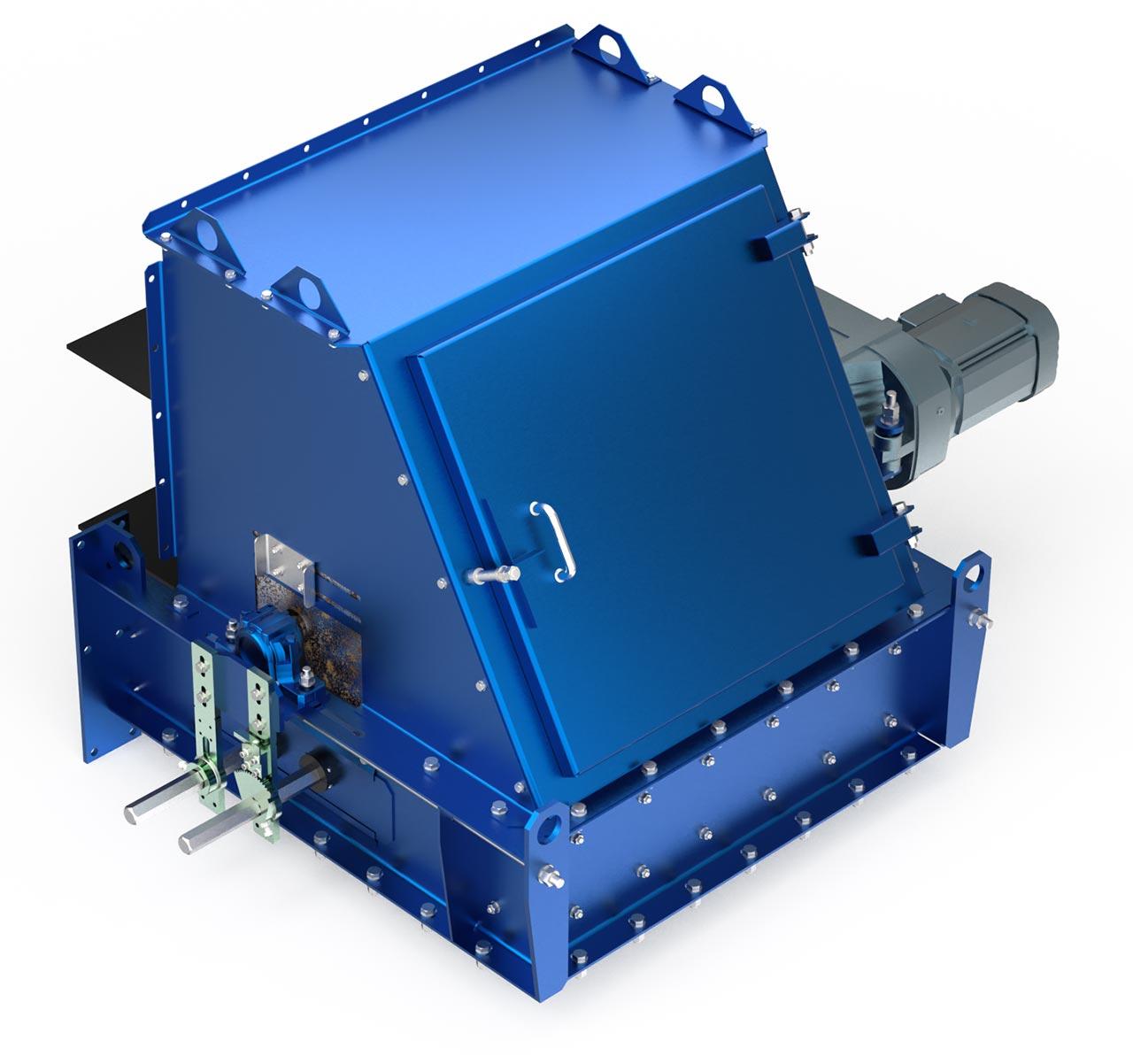

Using quick locks on the conveyor covers and especially easy operating locking system for the safety mesh, the maintenance work can be done as fast as possible.

This product is an example of a solution tailored to one of our customers. When necessary, we do design the components to suit the customer’s need.

Contact Us

Get in touch with the product manager Petteri Viinanen (040 585 5485, info@sysi.fi) and we’ll tailor a solution to your need.