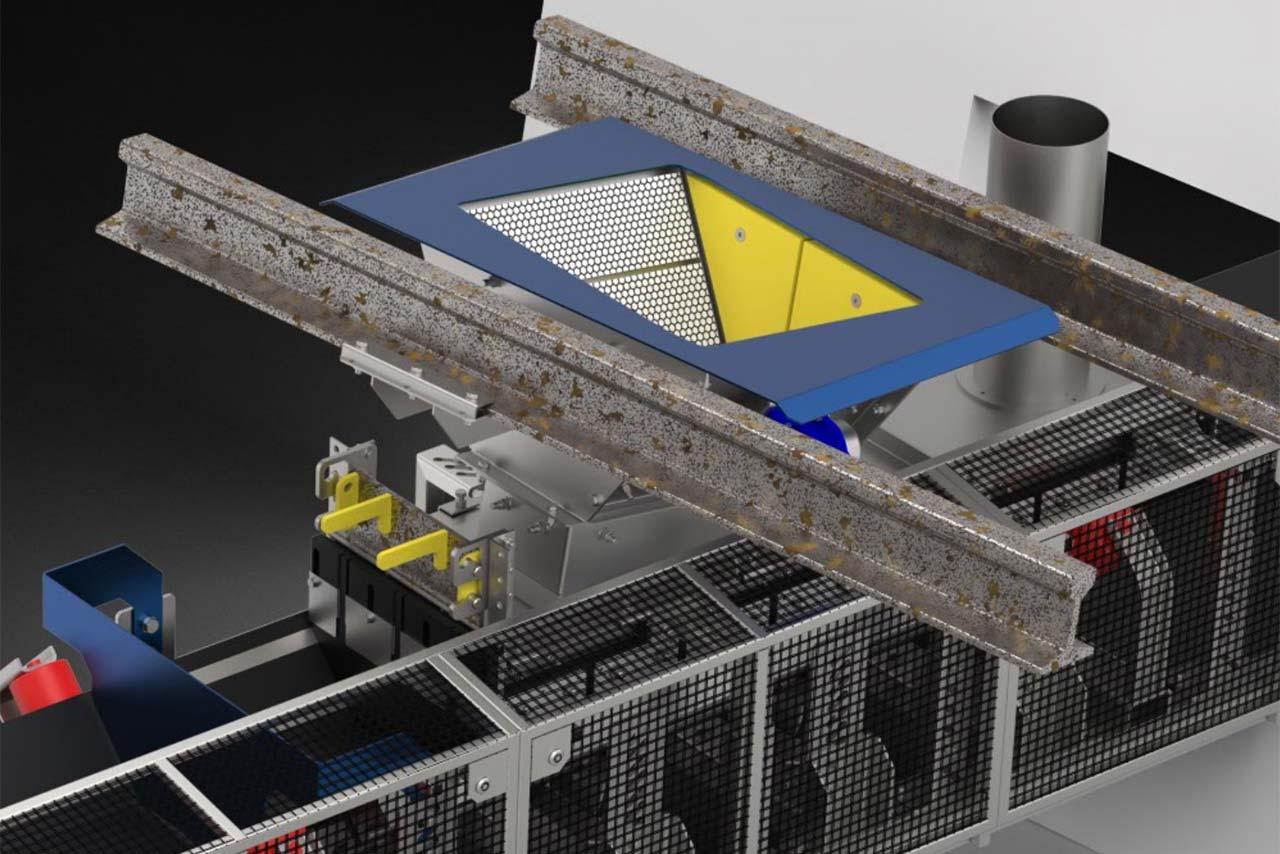

Dedusting

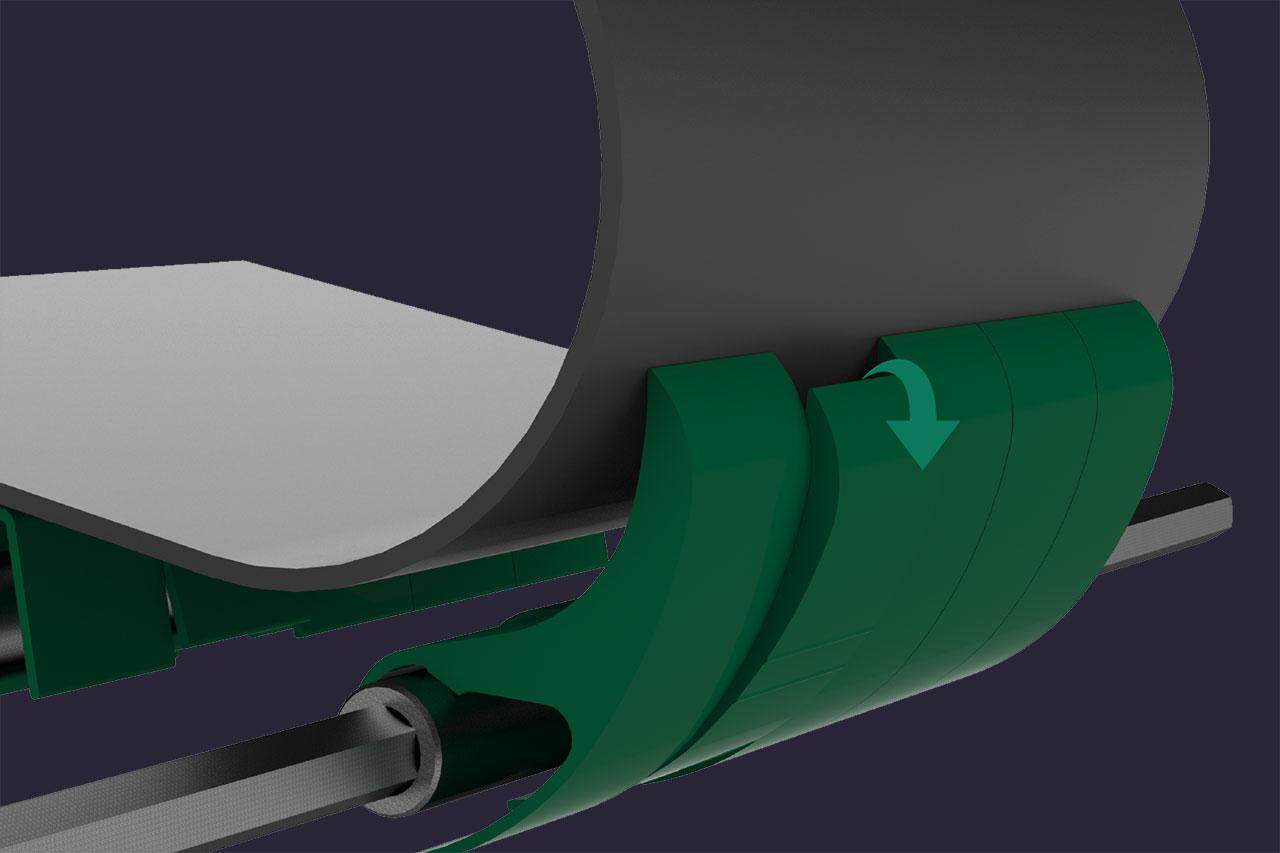

When discussing dedusting measures, we start by putting the mechanical prequisites in top condition first. With small things, it is possible to control the airflow in the chute and to seal the equipment so that you can control the dust.

Depending on the materials and process, you may want to get rid of the fines or you may want to return them to the material flow for example with a very fine water fog. In some cases, even a small amount of moisture will be a problem, which means that a decentralized dedusting unit could be the solution…or then to use a larger dedusting unit gathering the dust from various locations.

Again, learning about the material properties and operating conditions is the key information to the engineering.

Contact Us

Get in touch with the product manager Petteri Viinanen (040 585 5485, info@sysi.fi) and we’ll tailor a solution to your need.